The recent release of a new EU proposal to restrict per- and polyfluoroalkyl substances (PFAS) in textiles has garnered significant attention from the global textile industry. The proposal not only significantly tightens PFAS residue limits but also expands the scope of regulated products. This is expected to have a profound impact on China’s textile exports to the EU. As a major supplier of textiles to the EU, China exports €12.7 billion annually to the EU. Related companies need to plan ahead to mitigate trade risks.

I. Core Content of the Proposal: A “Cliff-like” Tightening of Limits and a Comprehensive Expansion of Coverage

This new EU PFAS restriction proposal goes beyond a simple adjustment of standards; rather, it represents a breakthrough in both the intensity of control and the scope of coverage, significantly exceeding previous regulations.

1. The limit has been lowered from 50ppm to 1ppm, increasing the stringency 50 times.

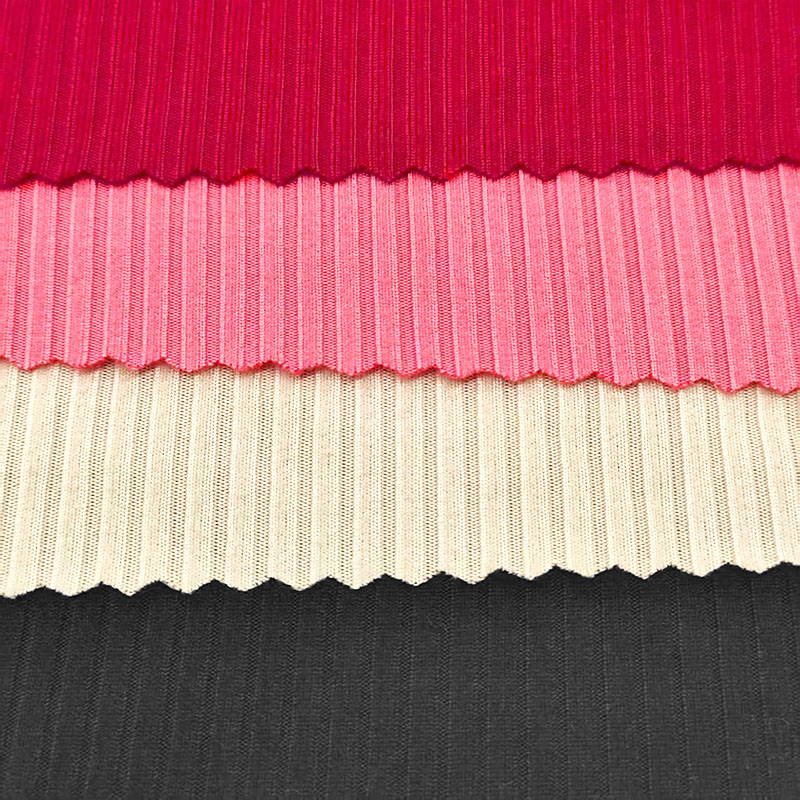

PFAS, due to their water-, oil-, and stain-resistant properties, are widely used in textiles such as outdoor clothing, sportswear, and home textiles (such as waterproof mattresses and stain-resistant curtains). The EU’s previous limit for PFAS in textiles was 50ppm (50 parts per million), but the new proposal lowers the limit directly to 1ppm, effectively requiring PFAS residues in textiles to be kept to a “near-zero” level.

This adjustment reflects the EU’s concerns about the environmental and health risks of PFAS. PFAS, known as “permanent chemicals,” are difficult to degrade in the natural environment and can accumulate in the food chain, potentially posing harm to the human endocrine and immune systems. The EU has been promoting a “PFAS-free environment” strategy in recent years, and this tightening of the limit for textiles is a significant implementation of this strategy in the consumer sector.

2. Covering All Categories, with Almost No Textiles Exempt

The new proposal breaks the previous EU’s “category-limited” control of PFAS in textiles, expanding the scope of control from “certain functional textiles” to nearly all textile categories:

Apparel: including outdoor wear, sportswear, children’s wear, formal wear, underwear, etc.;

Home Textiles: covering mattresses, sheets, curtains, carpets, pillows, etc.;

Industrial Textiles: such as waterproof tents, sunshades, and medical protective textiles.

The only exception is “basic textiles made from natural fibers without any functional treatment” (such as undyed, uncoated pure cotton greige fabric). However, these products account for a very small proportion of exports to the EU, and the vast majority of Chinese textile exports to the EU will be subject to control.

3. Clear Timeline: After a 60-day public comment period, the regulation is likely to take effect in 2026.

The proposal has entered the public comment period, which will last for 60 days (starting from the date of publication) and is primarily intended to collect feedback from EU member states, industry associations, businesses, and the public. Judging from the pace of EU environmental policy implementation in the past, such proposals typically do not undergo major adjustments after the public comment period. The legislation process is expected to be completed by the end of 2025, with formal implementation in 2026.

This means that Chinese textile companies only have a “buffer period” of approximately one to two years, during which they must complete technological upgrades, adjust their supply chains, and optimize their testing processes. Otherwise, they risk having their goods detained, returned, or even fined by EU customs.

II. Direct Impact on China’s Textile Foreign Trade: A €12.7 Billion Export Market Faces a “Compliance Test”

China is the EU’s largest source of textile imports. In 2024, Chinese textile exports to the EU reached €12.7 billion (approximately RMB 98 billion), accounting for 23% of the EU’s total textile imports. This involves over 20,000 exporting companies, including major textile exporting provinces such as Zhejiang, Jiangsu, Guangdong, and Fujian. The implementation of the new proposal will have a direct impact on Chinese companies in terms of costs, orders, and supply chains.

1. Sharply increasing cost pressure: Fluorine-free process conversion and specialized testing are both expensive.

For Chinese companies, meeting the 1ppm limit involves two key costs:

Technological transformation costs: Traditional fluorine-containing processes (such as those using fluorine-containing water-repellents) must be completely replaced with fluorine-free processes. This involves purchasing fluorine-free water-repellents, adjusting production processes (such as baking temperatures and dyeing techniques), and upgrading equipment. For example, for a medium-sized textile company with annual exports to the EU of US$10 million, the procurement cost of fluorine-free auxiliaries alone would be 30%-50% higher than traditional auxiliaries, and the equipment conversion costs are estimated to reach several million yuan.

Increasing testing costs: The EU requires textiles to pass “PFAS-specific testing” before export, and the report must be issued by an EU-approved third-party testing agency. Currently, the cost of a single PFAS test is approximately €800-1,500 per batch. Previously, under the 50ppm limit, most companies only needed to conduct spot checks. With the new proposal, batch-by-batch testing will be required. For a company exporting 100 batches annually, annual testing costs will increase by €80,000-150,000 (approximately RMB 620,000-1.17 million).

2. Increased Order Risk: EU Buyers May Shift to Pre-screening Suppliers

EU brands (such as ZARA, H&M, and Uniqlo Europe) have extremely high requirements for supply chain compliance. Following the release of the new proposal, some EU buyers have begun adjusting their sourcing strategies:

Chinese suppliers are required to provide “fluorine-free process certification” and “PFAS test reports” in advance, excluding them from purchases.

Concerned about compliance risks, some small and medium-sized brands have reduced direct sourcing from China and are shifting to suppliers in the EU or Southeast Asian countries (such as Vietnam and Bangladesh). Although Southeast Asian companies also face technical bottlenecks, EU buyers prefer “local control.”

For small and medium-sized Chinese textile companies, failing to quickly meet compliance requirements could lead to the loss of orders. Large companies, while able to afford the restructuring costs, will also need to renegotiate pricing with EU buyers, squeezing their profit margins.

3. Increased customs inspection risks: Non-compliant goods will face detention and return.

EU customs will become the “executor” of the new proposal. Upon implementation, EU member states’ customs will strengthen PFAS sampling and testing of imported textiles. Any PFAS content exceeding 1 ppm will result in on-site detention, and companies will be required to provide supplementary testing reports within a specified timeframe. If non-compliance is confirmed, the goods will be forcibly returned, and the company may be placed on the EU customs “priority monitoring list,” increasing the inspection rate of subsequent export goods to over 50%.

Previous EU environmental regulations on textiles (such as REACH and azo dye restrictions) have already resulted in some Chinese companies facing shipment rejections due to non-compliance. With the new, more stringent PFAS limits, the risk of rejections is expected to increase significantly. According to statistics from the China Chamber of Commerce for Import and Export of Textiles and Apparel, the return rate of Chinese textiles to the EU due to environmental compliance issues will be approximately 1.2% in 2024. This rate is likely to exceed 3% after the new proposal takes effect.

III. Response Path for Chinese Textile Companies: From “Reactive Compliance” to “Proactive Breakthrough”

Faced with the challenges of the EU’s new proposal, Chinese textile companies must abandon a “temporary response” mentality and instead build long-term compliance capabilities across the technology, supply chain, and market dimensions, transforming “compliance costs” into “competitive advantages.”

1. Technology: Accelerate the replacement of fluorine-free processes to seize the “green technology” high ground.

Fluorine-free processes are key to meeting EU limits. Companies can advance technological transformation in two ways:

Prioritize the use of proven fluorine-free additives: Fluorine-free products are currently available on the market that can replace fluorine-containing water repellents, such as plant-based water repellents and water-based polyurethane coatings. While these products are more expensive, their technical stability has been proven (for example, sports brands such as Anta and Li Ning have already adopted fluorine-free water repellent processes in their outdoor apparel).

Collaborate with research institutions to develop low-cost technologies: Small and medium-sized enterprises can collaborate with universities and industry research institutes (such as the China Textile Science Academy) to conduct “fluorine-free process cost reduction research.” For example, by optimizing additive ratios and improving production processes, the unit cost of fluorine-free processes can be reduced.

In addition, companies can explore the “natural fiber + functional improvement” approach—for example, leveraging the natural antibacterial and moisture-absorbing properties of flax and bamboo fibers to reduce reliance on PFAS functional additives. This, in turn, creates a “natural + environmentally friendly” product selling point to enhance product appeal to EU consumers.

2. Supply Chain: Establish “Full-Chain Traceability” and Preemptively Lock Down Testing Steps

Compliance isn’t just a “production-side” issue; it must be implemented throughout the entire supply chain:

Upstream Raw Material Control: Sign “PFAS-Free Supply Agreements” with fabric suppliers and additive manufacturers, requiring upstream companies to provide PFAS testing reports for their raw materials to eliminate contamination at the source;

Midstream Production Process Monitoring: Establish “PFAS Control Points” within the production workshop, such as regularly testing residual levels in dyeing tanks and coating equipment to prevent cross-contamination;

Downstream Preemptive Testing: Avoid relying on “post-testing” by EU customs. Instead, commission domestic, EU-accredited testing agencies (such as SGS China and Intertek China) to conduct specialized PFAS testing before goods are exported. This ensures that the reports comply with EU standards and reduces customs clearance risks.

3. Market: Diversify and Strive for a “Compliance Premium”

Facing compliance pressure in the EU market, companies can adopt a two-pronged strategy:

Expand non-EU markets to diversify risks: Increase efforts to explore emerging markets such as Southeast Asia, the Middle East, and South America. These markets currently have relatively loose regulations on PFAS (for example, Brazil and India have not yet issued PFAS limits for textiles), which can serve as a “complement” to the EU market;

Strive for a “Compliance Premium” from EU buyers: Proactively explain the increased costs of fluorine-free processes to EU brand owners and negotiate higher product pricing. In fact, EU consumers are more willing to pay for “eco-friendly products.” According to a survey by the European Consumers Association, textiles labeled “PFAS-free” can command a 10%-15% premium. Companies can gain pricing control by emphasizing their “environmental attributes.”

IV. Industry and Policy Support: Reducing the Burden and Empowering Enterprises

In addition to enterprises’ own responses, industry associations and government departments are also actively supporting Chinese textile foreign trade enterprises:

Industry associations are establishing a “response and communication platform”: The China Chamber of Commerce for Import and Export of Textiles and Apparel has organized several “EU New PFAS Proposal Interpretation Meetings,” inviting lawyers and testing experts to answer questions from enterprises. They also plan to establish a “fluorine-free process technology sharing library” to help small and medium-sized enterprises lower the technological barriers to entry.

Local governments are providing “technical transformation subsidies”: Zhejiang, Jiangsu, Guangdong, and other provinces have included “fluorine-free process transformation for textiles” in their local foreign trade support policies. Enterprises can apply for subsidies of up to 30% of the technical transformation costs and enjoy reduced testing fees.

The Ministry of Commerce is promoting the “China-EU Standards Dialogue”: The Ministry of Commerce has conveyed the reasonable demands of Chinese enterprises to the EU through the China-EU Joint Economic and Trade Committee mechanism, and is working to establish a “transition period” after the proposal takes effect to provide small and medium-sized enterprises with more time to adjust.

Post time: Aug-18-2025